¶ Introduction

We have a Brother NS50 computerised sewing machine in the space for sewing projects. It has the full range of standard features and stitches plus an automatic embrodiery function and multiple decorative stitch settings.

The different sewing feet and tools are stored in the flatbed attachment in the front of the machine.

¶ Specifications

- Induction Class: 🟡 Yellow Tool (Induction Required)

- Available Needle Sizes: 90/14 (Topstitch and Heavy-duty)

- Available Feet: Buttonhole, Overcasting, Monogramming, Zipper, Zigzag, Blind Stitch, Button Fitting

- Foot Size: 5mm

- Instruction Manual

- Last Service: Jan 2024

¶ Needle Types

90/14 Top-stitch (Blue rings): Suitable for most medium-weight fabrics

90/14 Heavy-duty (Purple end): Suitable for most heavy-weight fabrics

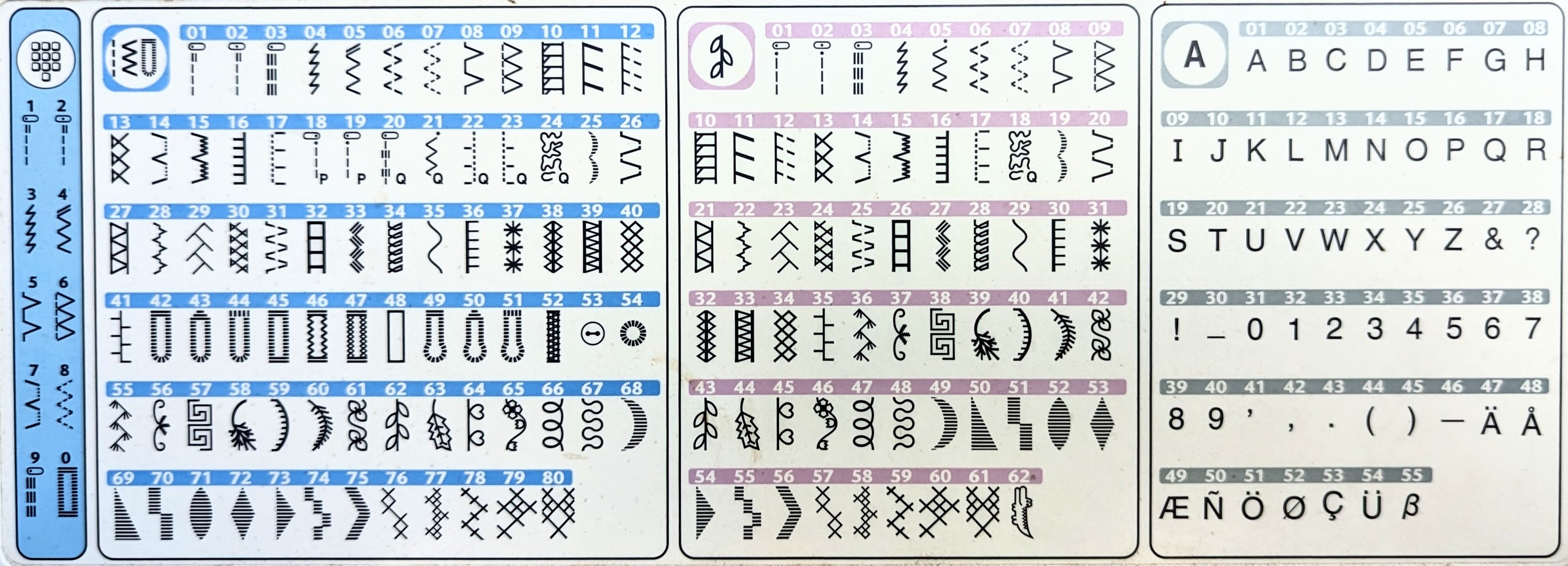

¶ Stitch Index

¶ Induction Process

🟡 This tool requires an induction before use.

To book an induction for this machine, please use the "book appointment" link from the member portal.

¶ Tool Safety

¶ Potential Hazards

| Potential Hazard | Details |

|---|---|

Entanglement |

The sewing machine has moving parts that can become entangled with hair or clothing. |

Sharp Element |

The needle of the sewing machine is a sharp element. There are also some guarded cutting edges that can cut hair if it is caught in it. |

¶ Operating Checklist

¶ Before Use

- Ensure the power cord and footpedal have been plugged into the machine.

- Ensure that a needle and sewing foot is installed in the machine. Use the appropriate needle for your fabric and thread.

- Ensure that the upper thread spool is installed and threaded.

- Ensure the bobbin is installed and threaded. Only use A-style (SA156) plastic bobbins with this machine.

- Remove and check the needle for wear or damage before use. Replace needle if it is blunt or has significant wear.

¶ During Use

- The sewing machine will not operate if the presser foot is not lowered. This is a common mistake that beginner users make.

- Make sure that you have enough thread in your upper thread spool and bobbin while sewing. It's easy for you to not notice that the bobbin has run out of thread while stitching.

- Consult the manual if you need help using particular stitches or setting up various parts of the machine.

- Replace the needle for every 4-6 hours of continuous use

- Ensure the tension is set correctly for your top thread. Consult page 57 (digital version page 59) of the manual for information on how to adjust thread tension.

¶ After Use

- If you have brought your own thread, make sure you remove your bobbin and thread spool from the machine. It's okay to leave any BMS supplied thread in the machine.

- If you have taken any parts or tools from the flatbed storage compartment, make sure they go back.

- Disconnect the footpedal and power cable. Wind the footpedal cable loosely around the footpedal. Loosely fold the power cable over itself.

- Store the power cable and footpedal in the arch of the sewing machine and place the storage case over the machine.

- Remember to carry the sewing machine by the handle.

¶ Troubleshooting

If the machine jams and keeps jamming, the needle stutters and stops, or the handwheel is hard to turn, the bobbin enclosure may have rotated out of alignment. To fix, follow the instructions in Handwheel does not turn or is tight, referring to the maintenance procedures in the manual where indicated for removing the needle plate and cleaning the race.

- If the bobbin case was out of alignment, check that the needle has not been bent (which can happen when the needle tip hits the bobbin case) and replace it if it is, before beginning to sew again.